Semiconductor

GD Tech is recognized as the partner of choice for semiconductor capital equipment manufacturing companies because we are the best-positioned company to provide a complete turnkey system integration solution that spans engineering, machining, cleaning, surface treatment, assembly, integration and testing. In addition, we can uniquely handle major volume and design changes during the manufacturing process, while maintaining on time delivery. This provides equipment manufacturers with extreme flexibility when responding to fluctuations and dynamic market changes. With GD Tech's semiconductor manufacturing experience, our customers can consistently expect faster time-to-market and lower costs.

For the high technology intensive and yield-sensitive semiconductor fabrication environment, only the most qualified companies manufacture and service components that directly impact fabrication processes such as etch chambers and shower heads. GD Tech has the engineering depths and experiences to meet the semiconductor industry's most challenging application performance requirements, which enable us to be a strategic Original Parts Manufacturing (OPM) supplier to leading Original Equipment Manufacturers (OEMs). As customers increasingly demand broad capabilities under one-roof, GD Tech is strategically positioned to provide broad products & services.

Materials

GD Tech has experience with a variety of materials, including aluminum (extrude, cast & forged), high performance plastics (Vespel, Peek, Ultem, Teflon, Rexolite), stainless steel, titanium, copper and precious metal such as gold, platinum, silver or palladium. We'll work with you to select the best material for your application.

Manufacturing Capabilities

GD Tech is well equipped to meet the unique precision machine parts manufacturing demands of the semiconductor equipment manufacturing sector. We leak-test components for use in vacuum conditions. Machined parts are cleansed, assembled, and packaged in our clean area, which is isolated from the machine shop production floor to control contamination. All products delivered or assembled directly conform to RoHs standards.

Below are some highlights of our capabilities:

· Multi pallet horizontal flexible manufacturing systems, 7-Axis / 5–Axis CNC milling, horizontal CNC milling, vertical CNC milling, gantry CNC milling, CNC turning, wire cut & die sinking EDM services and more.

· For front-end semiconductor parts, materials are isolated and machines are dedicated to avoid cross contamination.

· High pressure washing / precision & ultrasonic cleaning / chemical cleaning

· Mechanical & electromechanical assembly / cleanroom assembly and packaging

· Jitterbug finishing

· Electropolishing & mechanical polishing

· Welding & helium leak testing / hydrostatic pressure test

· Functional and dimensional inspection

· ISO 6 (Class 1000) cleanroom

· Heat treating and surface treatment

GD Tech's long term commitment to state of the art assembly, integration and test facilities make us a leading supplier of subassemblies for semiconductor wafer processing equipment. Rapid prototyping, assembly and testing of customer concepts facilitate an efficient design iteration process to respond to our customers "time to market" equipment. In house capability to design and fabricate tooling, assembly and test fixtures further enhances our ability to respond quickly to customer needs.

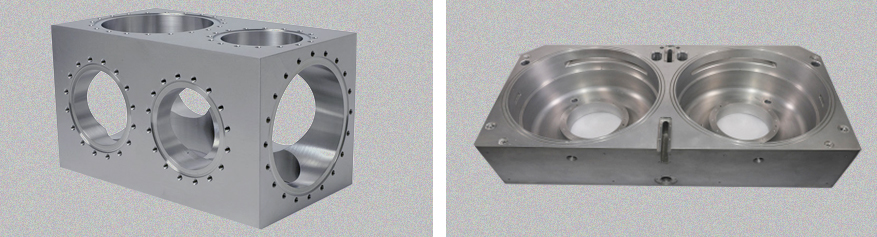

Vacuum Chambers Manufacturing

GD Tech specializes in stainless-steel and aluminum chambers with large, complex geometries. Choose from vacuum components, weldments, custom vacuum chambers, and fully integrated vacuum systems-manufactured to your specifications.

As a long-time supplier of custom-made equipment and systems, GD Tech offers custom vacuum chamber construction for a number of industrial applications, including semiconductor equipment, research, PV tools and particle accelerator components. With expertise as a manufacturer of aluminum, plated steel, and stainless-steel vacuum chambers, GD Tech employs the latest technology in 5-axis machining and precision welding to efficiently produce vacuum chambers in production quantities.

Our dedicated engineering staff is well versed in the proper manufacture of custom vacuum chambers, from assembly through final test and packaging protocol.

Semiconductor Manufacturing Experience

GD Tech provides precision machining and complex assembly for a wide range of front-end and back-end semiconductor equipment, including CVD/PVD/RTP etch systems.

Our systems and equipment are a perfect fit for these types of parts that require the utmost attention to detail. Multi-axis machining, chemical cleaning, cleanroom Control and Packaging, welding & helium leak Testing are just some of the ways GD Tech has adapted to ensure excellent quality Semiconductor components and assemblies.

· Chemical vapor deposition (CVD)

· Physical vapor deposition (PVD)

· Molecular beam epitaxy (MBE)

· Electrochemical deposition (ECD)